Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

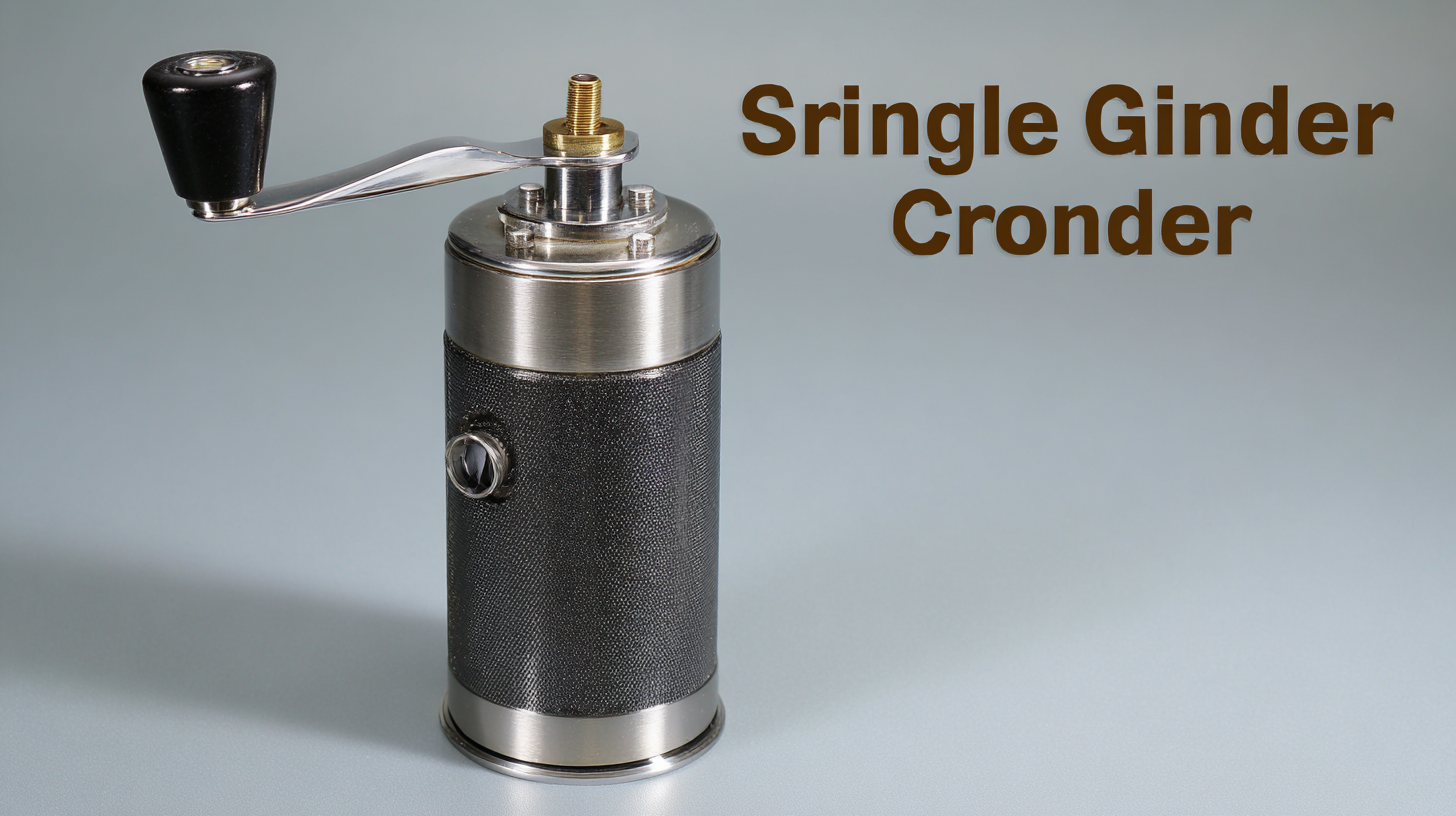

The global coffee grinder market is evolving rapidly, with the single dose coffee grinder emerging as a frontrunner in innovation and consumer preference. According to a recent report by ResearchAndMarkets, the coffee grinder market is projected to grow at a CAGR of 5.6%, driven by the increasing demand for precision brewing and specialty coffee experiences among consumers. This surge is notably influenced by the rising popularity of single-serve coffee methods that prioritize freshness and flavor. As we look towards 2025, advancements in technology, such as smart grinding and enhanced customization features, are set to redefine the landscape of coffee preparation tools. Chinese manufacturing stands out in this arena, leveraging unmatched quality and scalability to meet the growing global export demand for high-performance single dose coffee grinders. This blog will explore the technological trends shaping this sector and the benefits that the latest innovations bring to both consumers and manufacturers alike.

The coffee grinder market has witnessed a remarkable transformation in recent years, with Chinese manufacturers emerging as global leaders in the production of single-dose coffee grinders. This rise can be attributed to several factors, including advanced manufacturing techniques, a focus on quality control, and an unwavering commitment to innovation. Chinese companies have embraced state-of-the-art technology, allowing them to produce high-performance grinders that cater to the demands of coffee enthusiasts around the globe.

In addition to technological advancements, Chinese manufacturers have prioritized the consistency and quality of their products. Rigorous testing and quality assurance processes ensure that each grinder meets international standards, elevating the overall reputation of Chinese manufacturing in this niche market. Moreover, competitive pricing strategies have enabled these manufacturers to capture significant market share, making their products accessible to a wider audience. As a result, the perception of Chinese-made coffee grinders is steadily shifting, positioning them not only as affordable options but also as benchmarks for quality and performance in the coffee industry.

The single dose coffee grinder market has seen remarkable growth in recent years, with an estimated value of over $1 billion globally in 2022. However, manufacturers within this highly competitive sector face several challenges that hinder their ability to maintain consistent quality and meet rising consumer demands. One primary challenge is the fluctuation in raw material costs, which can impact production schedules and profit margins, forcing companies to adapt their pricing strategies frequently. According to recent reports, over 45% of manufacturers cite supply chain disruptions as a significant obstacle.

Additionally, the rapid pace of technological advancements presents another hurdle. As consumers increasingly seek grinder models that offer innovative features and superior performance, manufacturers must invest heavily in research and development to keep pace with these changes. A recent survey revealed that nearly 60% of companies believe that staying updated with the latest technology is crucial for sustaining their market position. This innovation pressure demands not just funding, but also skilled labor, which can be scarce in some regions, affecting overall productivity and output quality.

| Dimension | Value |

|---|---|

| Annual Production Volume | 500,000 units |

| Export Percentage | 85% |

| Average Retail Price (USD) | 150 |

| Main Export Markets | North America, Europe, Asia |

| Common Manufacturing Materials | Stainless Steel, Plastic, Aluminum |

| Key Challenges Faced | Quality Control, Competition, Supply Chain Issues |

| Average Production Lead Time | 4-6 weeks |

| Technology Adoption Level | High |

In the realm of coffee grinders, quality control is a pivotal challenge in mass production. Many manufacturers aim for high output, but this can sometimes compromise the very quality that consumers expect. Common issues in quality control include inconsistent grind sizes, motor malfunctions, and subpar materials that can lead to a shorter lifespan of the product. It is essential for producers to establish rigorous testing protocols to ensure that every unit meets the desired standards.

Tips for improving quality control include investing in automated inspection technology, which can help catch defects early in the production process. Additionally, establishing a feedback loop with customers can provide valuable insights into potential weaknesses and promote continuous improvement. Regular training sessions for staff on quality assurance can further enhance the overall standards of manufacturing. By prioritizing quality control, manufacturers not only enhance their reputation but also foster loyalty among coffee enthusiasts worldwide.

Consistent adherence to quality benchmarks will ultimately position a company as a leader in the global market. Implementing these strategies not only bolsters the brand identity but also satisfies the discerning tastes of coffee lovers who demand perfection in every cup.

The future of coffee grinder design is being significantly influenced by groundbreaking innovations that cater to the evolving needs of consumers. As the home coffee machine market grows, manufacturers are stepping up their game, integrating advanced features that prioritize convenience, sustainability, and user experience. For instance, the recent attention on modular designs ensures that coffee enthusiasts can customize their setups to achieve the perfect brew, appealing to a wider audience that craves both aesthetics and functionality.

In the realm of sustainability, innovative concepts like coffee machines made from recycled materials are making waves. These designs not only reduce waste but also reflect a growing commitment within the industry to environmentally friendly practices. Furthermore, brands are exploring entirely biodegradable capsules, which aim to eliminate traditional waste associated with coffee consumption. Such strides in innovation highlight an industry that is both responsive and forward-thinking, paving the way for a new era in coffee grinder design that aligns with contemporary values and consumer demands.

In the competitive landscape of coffee grinder exports, Chinese manufacturers are showcasing unmatched quality that sets them apart on the global stage. This remarkable achievement is a result of combining advanced technology with traditional craftsmanship, allowing for the production of single dose coffee grinders that meet the highest standards of performance. Companies have invested heavily in research and development to innovate designs that not only enhance the user experience but also ensure durability and precision in grinding.

Furthermore, China's strategic positioning in the export market leverages an extensive supply chain and competitive pricing, making its products increasingly attractive to international buyers. Manufacturers are prioritizing eco-friendly materials and practices, aligning with the growing trend of sustainability that resonates with consumers worldwide. As coffee culture continues to flourish, these exceptional factors contribute to China's rise as the global export leader in single dose coffee grinders, cementing its reputation for delivering products that satisfy even the most discerning coffee enthusiasts.